Apr 22, 2012

Making PCB with Roland Modela MDX-20 (Fritzing version)

This post describes how to create PCB with Roland Modela MDX-20 mill machine using Fritzing open souce software. The instruction using Eagle is described in another post.

Software:

- Fritzing (PCB layout editor)

- a vector graphic editor (i.e. Adobe Illustrator)

- bitmap graphic editor (i.e. Adobe Photoshop)

- Ubuntu Operating System

- Fab modules (See video instruction of the installation)

Hardware:

- Roland Modela MDX-15 or 20

- DATRON Fish tail End Mills for PCB Milling (Art. No. 0068106. 0.6mm flute diameter. 3mm shank diameter and Art. No. 0068108 for 0.8mm flute diameter)

- PS3 spindle from Roland (3mm shank diameter)

- Single sided copper PCB board (160x100mm is enough): You can buy them at Partco Oy in Helsinki.

- Arduino Duemilanove (or equivalent Arduino)

- USB A-B cable (to connect the Arduino with PC)

- Electronic components (LED, resistors and photo registor)

- Addition to them, tools to solder components

Designing PCB layout with Fritzing

- Create new project

- Open Breadboard view (default view is breadboard)

- Add following componets on breadboard from parts

- Core parts > resistor (10KR)

- Core parts > resistor (220R)

- Core parts > LED

- Core parts > Photocell (LDR)

- Connecting parts with wires as you see in the attached schematic in the zip file

- Wires goes to GND should be in black. Wires go to 5V should be in red. The rest of wires can be in any color.

- Change breadboard view to PCB view

- Click brean PCB board and change the shape to Arduino in the inspector

- Autoroute (Menu > Routing > Autoroute)

- Move routes if they are crossing each other. Double click a wire to create / remove a corner

- Move the routes which go outside of the Arduino shield area

- Create ground plane to reduce noise and stabilize the circuit. (Menu > Routing > Ground Fill > Ground Fill)

- Export PCB view as PDF (Click “Export for PCB icon at the bottom of the window). It generates three PDF files as follows:

- fritzing_sketch_etch_copper_bottom.pdf (PCB for milling)

- fritzing_sketch_etch_mask_bottom.pdf (PCB for drilling)

- fritzing_sketch_etch_silk_top.pdf (It’s empty for this example)

- Note: Please remember black part in the PDF will be milled.

Modify milling and drilling PDF with a vector graphic editor

- Open fritzing_sketch_etch_copper_bottom.pdf in Adobe Illustrator

- Create new layer

- Paste all vectors in fritzing_sketch_etch_mask_bottom.pdf into fritzing_sketch_etch_copper_bottom.pdf (Position of both layout should be matched in the file)

- Change the size of Artboard area. It is recommended to have as little margin as possible on the outside of Arduino shield

- Save as new Illustrator file

- Drill size is too big thus you need to diameter of the drill holes to 0.9mm diameter. Please note that there are a few ellipse shape on top of each other. You need only one filled with black color.

- Export each layer (mill and drill) as PNG files. (Menu > File > Export

- Check “Use Artboards, PNG as format and click

- Resolution should be 500dpi and white as background color in PNG options and press OK.

Modify milling and drilling PDF with a bitmap graphic editor

- Open a PNG file for milling in Adobe Photoshop

- Invert the image (Menu > Image > Adjustment > Invert)

- Mirror the image (Menu > Image > Image Rotation > Flip Canvas Horizontal)

- Open a PNG file for drilling

- Only mirror the image

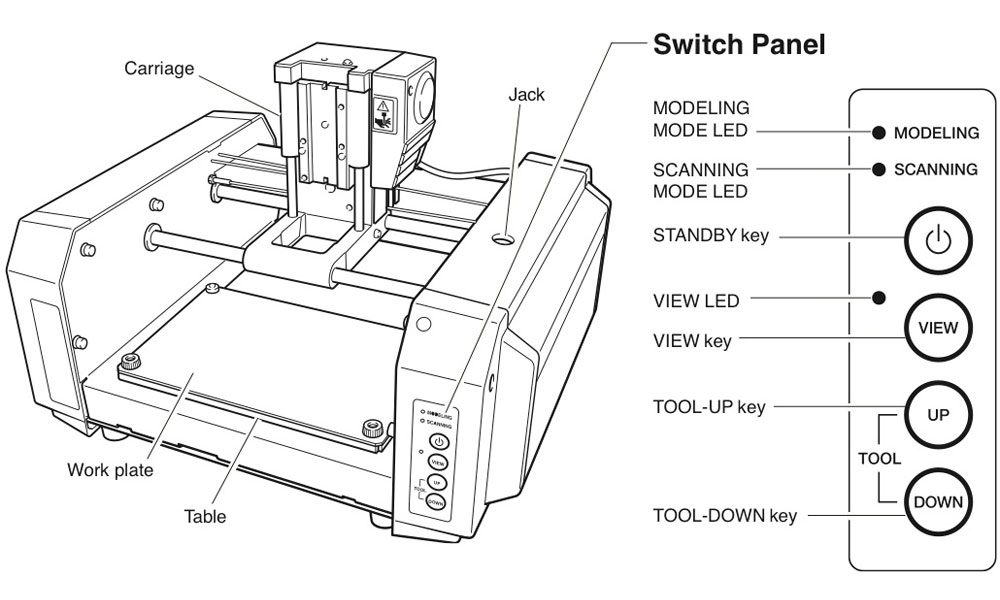

Install a end mill

You need to install the appropreate end mill. The user matual is MDX-20-15_USE_ENGLISH_R5.pdf. and read the instructions from page 26. Use the PS-3 spindle which has 3mm shank diameter.

End mills

- 0.6mm flute diameter with 3mm shank diameter for milling

- 0.8mm flute diameter with 3mm shank diam for drilling and milling the outline of the board.

Please use the end mill that is designed for printed circuit boards. Otherwise it will destroy the mill. We use DATRON Micro-Toothed End Mills (Art. No. 00686506 for 0.6mm and 0068110 for 1.0mm).

Place a copper board on the work plate

There is a hole the left bottom corner on the work plate. This hole indicates the orizin of x and y positions. Fix another copper board (used one is fine) under the copper board to avoid from drilling the work plate itself. You can use double side tape to fix it on the plate.

Set depth-direction reference point

You need to set the depth-direction (z axis) reference point. This means that the 0 point of z axis. Position under the point will be negative and above the point will be positive.

- Press STANDBY key to switch on the machine.

- If VIEW LED is on, press VIEW key. This operation should move the end mill to the origin of x and y axis. If not, you might have on going job. The way to cancel the job is described in the next paragraph.

- If the end mill start moving in different directions, the machine has on going data. Don’t panic. Just press VIEW key again to stop the operation. It will move to the default position at the right hand side. To cancel the operaton completely, please look at “How to cancel on going operations”.

- VIEW LED should be flashing.

- Press TOOL-UP/DOWN key to set the depth-direction reference point (for !PZ command in the RML file) . Long press will move the mill continuously. A short press will move the mill by 1mil. You can also unscrew the milling bit to place it on the copper board.

Send milling data to Roland Modela CNC machine

- Open Fab modules in Ubuntu OS

- Select Roland Modela (.rml)

- Select “mill trace (1/64) in the pulldown mene at the top of the window. To: path area in the window will automatically be filled with default values.

- Change radius to 0.3 ( = 0.6mm diameter)

- Click “make .path”. This command generates a tool path for the modela CNC machine

- Click “send it!” will print the PCB.

- Note: you can move the mill for a test. Fill xmin and ymin in to: rml area in the window and click “move to xmin, ymin”. This command simply move the end mil to the given position.

- Note: Be ready to press VIEW key anytime in the beginning of operation to avoid further damage in case. Pressing VIEW key always pause the operation immediately. Please note it won’t cancel the operation. This means that it will resume when you press the VIEW button again.

Send drilling data to Roland Modela CNC machine

- Change the end mill to 0.8mm diameter

- Open Fab modules in Ubuntu OS

- Select Roland Modela (.rml)

- Select “(1/32) in the pulldown mene at the top of the window. To: path area in the window will automatically be filled with default values.

- Change diameter to 0.4 radius (0.8mm diameter)

- Click “make .path”. This command generates a tool path for the modela CNC machine

- Click “send it!” will print the PCB.

- Note: you can move the mill for a test. Fill xmin and ymin in to: rml area in the window and click “move to xmin, ymin”. This command simply move the end mil to the given position.

- Note: Be ready to press VIEW key anytime in the beginning of operation to avoid further damage in case. Pressing VIEW key always pause the operation immediately. Please note it won’t cancel the operation. This means that it will resume when you press the VIEW button again.

How to cancel on-going operations

- Press View key first if the green LED next to the button is not off.

- Press TOOL-UP and TOOL-DOWN keys at the same time.

- The VIEW key will flash while deleting.

- The flash stops when The deletion is finished.

- Please also check Roland MODELA MDX-20 printer window to check if there is not pending jobs. You can access it from Start > Printers and Faxes.

- After the deletion is completed, you can send a new file.

Soldering

See this video tutorial.

- Solder small components first and move to bigger components.

- Do not forget some of components has polarity. e.g. LED

- In the case of IC, solder only one pin at the corner and fix the IC in the right place. After the IC is in the right position, you can solder the rest of pins.

- When you need to remove components, watch this tutorial first.

- Don’t solder Arduino!